Air Bearing Turbo Blower

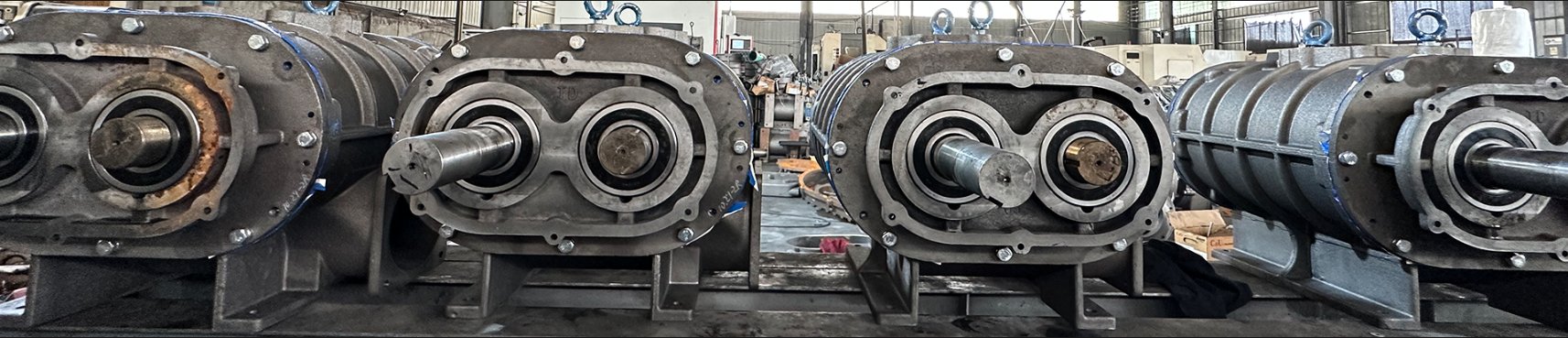

- AirMMax AMLT Roots Blower

- AirMMax AMLT+ Roots Blower

- AirMMax AMSR Roots Blower

- AirMMax AMZG Roots Blower

- AirMMax Turbo Blower Aerator

- Air Bearing Turbo Blower

- Magnetic Bearing Turbo Blower

- AirMMax AMSR Biogas Blower

- AirMMax Vapor Compressor

- AirMMax Stainless Steel Roots Blower

- AirMMax Multistage Centrifugal Blower

- AirMMax Accessories

AirMMax air bearing turbo blower is high speed centrifugal blower, which is widely used for water treatment, shrimp farming, cement plant, oil and gas, food etc.

Turbo Blower Core Technology

High Efficient Impeller

AirMMax turbo blower adopt forged aluminium alloy material and machined by five axis CNC machine, which ensure impeller higher rotation speed and higher efficiency.

High Efficient VFD

AirMMax turbo blower is controlled by high efficiency VFD with working frequency range 0-2000Hz to adjust air flow and pressure.

Permanent-magnet Synchronous Motor

AirMMax turbo blower is high efficient permanent magnet synchronous motor rotating maximum at 100.000rpm with efficiency reach 98%.

Touch Screen Control Panel

AirMMax turbo blower is equipped with touch screen, which is easy to operate.

Mobile Phone Remote Control

AirMMax turbo blower can be monitored and operated by mobile phone wherever you are.

Turbo Blower Size Table:

| Model | 3HP | 5.5HP | 7HP | 10HP | 15HP | 20HP | 30HP | 40HP | 50HP | 75HP | 100HP |

| Discharge Pressure kpa | Air Flow(m3/min),20℃,Humidity60%, 1atm | ||||||||||

| 30 | / | / | 7 | 10 | 12 | 18 | 29 | 43 | 52 | 88 | 107 |

| 40 | 2.5 | 5 | 6 | 9 | 11 | 16 | 27 | 38 | 47 | 76 | 95 |

| 50 | / | / | 5 | 8 | 10 | 14 | 24 | 33 | 40 | 59 | 77 |

| 60 | / | / | 4.5 | 7 | 9 | 12 | 21 | 28 | 35 | 53 | 69 |

| 70 | / | / | 4 | 6 | 8 | 9 | 19 | 25 | 31 | 46 | 63 |

| 80 | / | / | 3 | 5 | 7 | 8 | 18 | 22 | 28 | 41 | 55 |

| 90 | / | / | / | / | / | / | 15 | 19 | 25 | 37 | 50 |

| 100 | / | / | / | / | / | / | 13 | 17 | 22 | 34 | 45 |

| 110 | / | / | / | / | / | / | / | / | / | 29 | 41 |

| 120 | / | / | / | / | / | / | / | / | / | / | 38 |

| Shaft Power(kw) | 2.2 | 4 | 5 | 7.5 | 11 | 15 | 23 | 30 | 38 | 58 | 75 |

| Blower Power(kw) | 3 | 5.5 | 6.5 | 9 | 12.5 | 17.5 | 28 | 37 | 44 | 68 | 83 |

| Model | 125HP | 150HP | 175HP | 200HP | 250HP | 300HP | 350HP | 400HP | 500HP | 600HP | 800HP |

| Discharge Pressure kpa | Air Flow(m3/min),20℃,Humidity60%, 1atm | ||||||||||

| 30 | 142 | 173 | 196 | 222 | 261 | 288 | 334 | 371 | / | / | / |

| 40 | 120 | 150 | 172 | 190 | 228 | 256 | 296 | 335 | 430 | 540 | 747 |

| 50 | 95 | 115 | 129 | 156 | 196 | 225 | 270 | 311 | 384 | 490 | 622 |

| 60 | 87 | 105 | 110 | 140 | 170 | 210 | 246 | 280 | 334 | 420 | 552 |

| 70 | 78 | 92 | 106 | 120 | 155 | 181 | 208 | 235 | 298 | 378 | 477 |

| 80 | 70 | 85 | 98 | 110 | 136 | 160 | 190 | 220 | 260 | 336 | 429 |

| 90 | 62 | 70 | 79 | 94 | 122 | 138 | 163 | 186 | 240 | 302 | 380 |

| 100 | 56 | 65 | 75 | 88 | 110 | 126 | 150 | 174 | 224 | 282 | 357 |

| 110 | 50 | 59 | 70 | 82 | 101 | 120 | 140 | 161 | 202 | 268 | 330 |

| 120 | 45 | 53 | 65 | 75 | 90 | 116 | 131 | 148 | 188 | 250 | 309 |

| Shaft Power(kw) | 94 | 114 | 130 | 150 | 185 | 225 | 262 | 300 | 375 | 450 | 557 |

| Blower Power(kw) | 102 | 124 | 142 | 175 | 208 | 244 | 295 | 320 | 400 | 500 | 600 |

Turbo Blower Advantages:

High Efficient and Energy Saving

AirMMax turbo blower save 50% more electricity bill than traditional roots blower.

Easy Installation

AirMMax turbo blower is highly integrated, low weight and easy to move, user only need to connect power cable.

Plug and Play

AirMMax turbo blower is operated by the touch screen to adjust frequency and reach required air flow and pressure.

Easy Maintenance

AirMMax turbo blower is no lubricant oil type design, which keep away from the troubles brought by lubricant oil in traditional roots blower and centrifugal blower.

We can recover investment cost of turbo blower within 18 month by replacing roots blower.

| Model | 3HP | 5.5HP | 7HP | 10HP | 15HP | 20HP | 30HP | 40HP | 50HP | 75HP | 100HP |

| Discharge Pressure kpa | Air Flow(m3/min),20℃,Humidity60%, 1atm | ||||||||||

| 30 | / | / | 7 | 10 | 12 | 18 | 29 | 43 | 52 | 88 | 107 |

| 40 | 2.5 | 5 | 6 | 9 | 11 | 16 | 27 | 38 | 47 | 76 | 95 |

| 50 | / | / | 5 | 8 | 10 | 14 | 24 | 33 | 40 | 59 | 77 |

| 60 | / | / | 4.5 | 7 | 9 | 12 | 21 | 28 | 35 | 53 | 69 |

| 70 | / | / | 4 | 6 | 8 | 9 | 19 | 25 | 31 | 46 | 63 |

| 80 | / | / | 3 | 5 | 7 | 8 | 18 | 22 | 28 | 41 | 55 |

| 90 | / | / | / | / | / | / | 15 | 19 | 25 | 37 | 50 |

| 100 | / | / | / | / | / | / | 13 | 17 | 22 | 34 | 45 |

| 110 | / | / | / | / | / | / | / | / | / | 29 | 41 |

| 120 | / | / | / | / | / | / | / | / | / | / | 38 |

| Shaft Power(kw) | 2.2 | 4 | 5 | 7.5 | 11 | 15 | 23 | 30 | 38 | 58 | 75 |

| Blower Power(kw) | 3 | 5.5 | 6.5 | 9 | 12.5 | 17.5 | 28 | 37 | 44 | 68 | 83 |

| Model | 125HP | 150HP | 175HP | 200HP | 250HP | 300HP | 350HP | 400HP | 500HP | 600HP | 800HP |

| Discharge Pressure kpa | Air Flow(m3/min),20℃,Humidity60%, 1atm | ||||||||||

| 30 | 142 | 173 | 196 | 222 | 261 | 288 | 334 | 371 | / | / | / |

| 40 | 120 | 150 | 172 | 190 | 228 | 256 | 296 | 335 | 430 | 540 | 747 |

| 50 | 95 | 115 | 129 | 156 | 196 | 225 | 270 | 311 | 384 | 490 | 622 |

| 60 | 87 | 105 | 110 | 140 | 170 | 210 | 246 | 280 | 334 | 420 | 552 |

| 70 | 78 | 92 | 106 | 120 | 155 | 181 | 208 | 235 | 298 | 378 | 477 |

| 80 | 70 | 85 | 98 | 110 | 136 | 160 | 190 | 220 | 260 | 336 | 429 |

| 90 | 62 | 70 | 79 | 94 | 122 | 138 | 163 | 186 | 240 | 302 | 380 |

| 100 | 56 | 65 | 75 | 88 | 110 | 126 | 150 | 174 | 224 | 282 | 357 |

| 110 | 50 | 59 | 70 | 82 | 101 | 120 | 140 | 161 | 202 | 268 | 330 |

| 120 | 45 | 53 | 65 | 75 | 90 | 116 | 131 | 148 | 188 | 250 | 309 |

| Shaft Power(kw) | 94 | 114 | 130 | 150 | 185 | 225 | 262 | 300 | 375 | 450 | 557 |

| Blower Power(kw) | 102 | 124 | 142 | 175 | 208 | 244 | 295 | 320 | 400 | 500 | 600 |